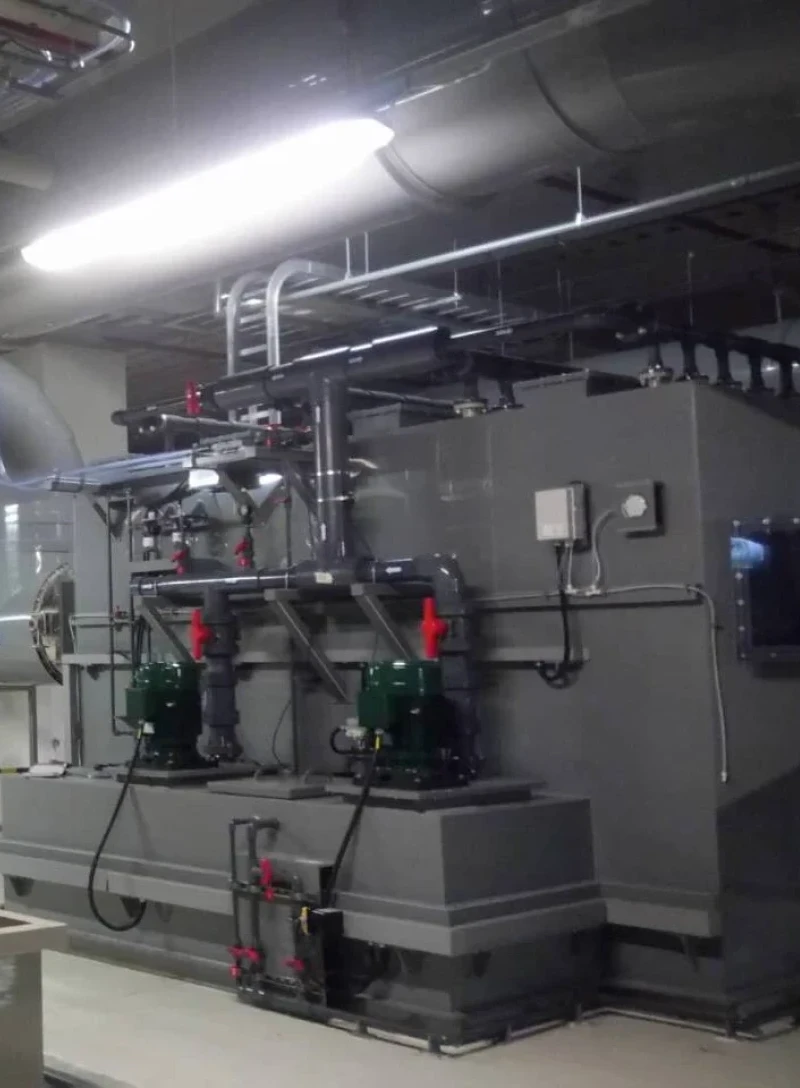

Advantages Introduction

- Patented Design: Removes 90–95% of PM1.0–2.5 particles; useful for resource recovery in chemical/fertilizer processes.

- 95–99% removal efficiency for high-concentration acids/bases, odors, and soluble particulates.

- Specifically optimized for the Standard Acid/Base Waste Streams (specifically the "5 acids and 1 base" common in semiconductor mfg.) used in the semiconductor industry with low maintenance costs.

System Features

- The use of packing with a three-dimensional (3D) structured design provides a larger specific surface area and a structural framework that ensures complete and uniform airflow distribution. This design enhances the contact and mass transfer between the gas and liquid phases, allowing for a lower liquid-to-gas ratio while simultaneously increasing removal efficiency.

- Through multi-stage configurations, the system utilizes nucleation-based particle growth and interception to effectively remove particulate matter. The process provides high-efficiency treatment for inorganic gases and odors.

- By utilizing various wire diameters and mesh combinations, the system can achieve a 99% removal rate for 2μm acid mists and water mists. It effectively treats droplets to prevent the overflow of pollutants from the scrubber outlet.

Applicable Industries

- Semiconductor and Waste Treatment industries.

- Optoelectronic Panels, PCB, and Electroplating.

- Fertilizer, Chemical, and Pharmaceutical industries.

Equipment processing efficiency

| Treatment Items | Treatment efficiency |

| Hydrofluoric acid (HF) | ≧99% |

| Inorganic acid and alkali waste gas | ≧95%~99% |

| Nitrogen Oxides (NOx) | ≧95% |

| Odor (Acetic acid, hydrogen sulfide, methanethiol, ethanethiol, dimethyl sulfide) | ≧95% |

| PM2.5~PM10 Particle Treatment | ≧90%~95% |

| PM1.0~PM2.5 Particle Treatment | ≧80%~90% |